- 26/01/2026

- Endress+Hauser

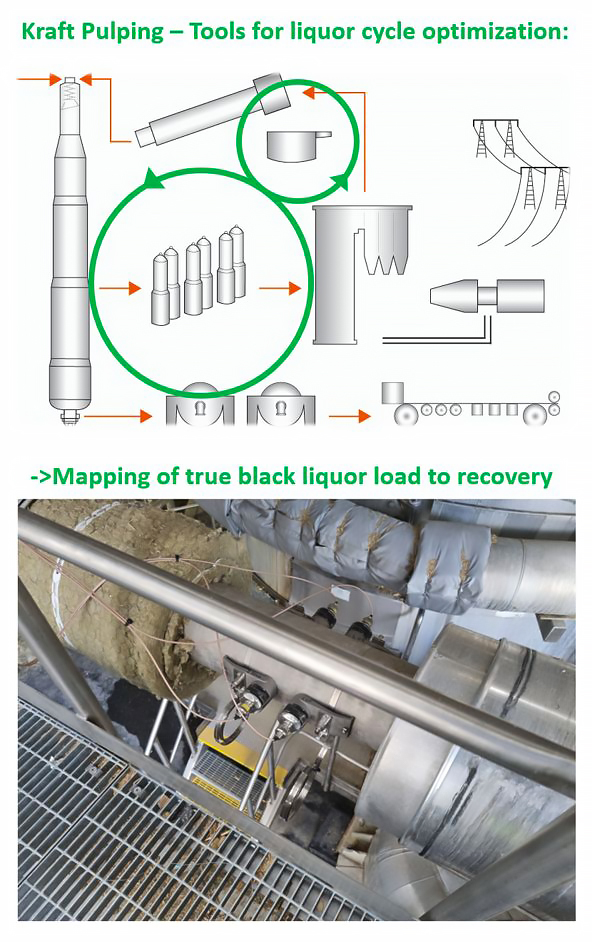

Accurate management of black liquor in pulp and paper mills

Challenges in measuring black liquor

During operation, measurement values related to black liquor often lack certainty and carry risks. Mills still have to rely on this data to maintain liquor balance in the digester and stabilize the liquor cycle. When information is inaccurate, the hydraulic load on the evaporation and recovery system is affected, leading to lower operational efficiency and increased costs.

Another challenge is the “silo effect” between individual operating units. This separation creates bottlenecks, dead loads, and reduces the overall efficiency of the mill. The lack of a comprehensive view of liquor balance makes root cause analysis and process optimization difficult.

3G Acoustic PROSONIC Solution

The non-invasive 3G Acoustic PROSONIC device provides accurate and continuous monitoring of black liquor. The device is designed for long-term installation, while also being flexible for temporary monitoring applications, with installation time of only about one hour and the ability to connect directly to the mill’s DCS system.

By providing precise measurement data, PROSONIC supports root cause analysis and KPI tracking throughout the process from cooking to evaporation. Eliminating uncertainty in measurement helps mills make correct decisions, reduce operational bottlenecks, and improve overall efficiency. At the same time, this technology helps break down barriers between departments, creating transparency and coordinated collaboration across the entire system.

Proven global performance

3G Acoustic PROSONIC has been successfully applied in many Kraft mills worldwide, delivering high reliability, improved operational performance, and clear economic benefits.