- 26/01/2026

- Valmet Flow Control

Tested and Proven – Part 2/3: Independent Testing and Approval

Equivalent Quality

Certification and approval according to standards are usually the best way to ensure quality and reliability objectively. Test data and results become easier to understand and compare when there are common methods and criteria. By providing type testing for the ordered valves, we bring peace of mind to customers.

Demand for Proven Performance

Valves ordered by customers are often type-approved for performance factors such as emissions, fire safety, and flow characteristics. These tests are carried out according to international standards, under the supervision of independent certification organizations. The key factors influencing valve purchasing decisions usually include: safety level, sustainability, operational efficiency, and financial effectiveness throughout the product lifecycle.

Therefore, we often conduct multi-cycle testing. In some cases, the testing process can last for many years and reach millions of cycles. Leakage emission testing can last up to six weeks, including 100,000 cycles. Our valves are designed to ensure maximum durability and reliability throughout their lifecycle, meeting even the most demanding customer requirements.

Measuring the flow coefficient helps select the accurate and reliable valve with Nelprof sizing software.

Understanding customer requirements

Understanding customer processes and requirements helps us define realistic objectives during product development. Testing products under harsh conditions is clear proof of their superior advantages. With decades of accumulated experience, we are a reliable partner, helping customers choose valves to achieve their goals more effectively and intelligently.

Advanced and Comprehensive Quality Management System

At Valmet, we apply a strict internal quality system. Quality requirements extend across all aspects of product research and development testing. We often set standards for testing equipment even higher than the manufacturer. Measuring devices are regularly maintained and calibrated.

High-standard testing facilities

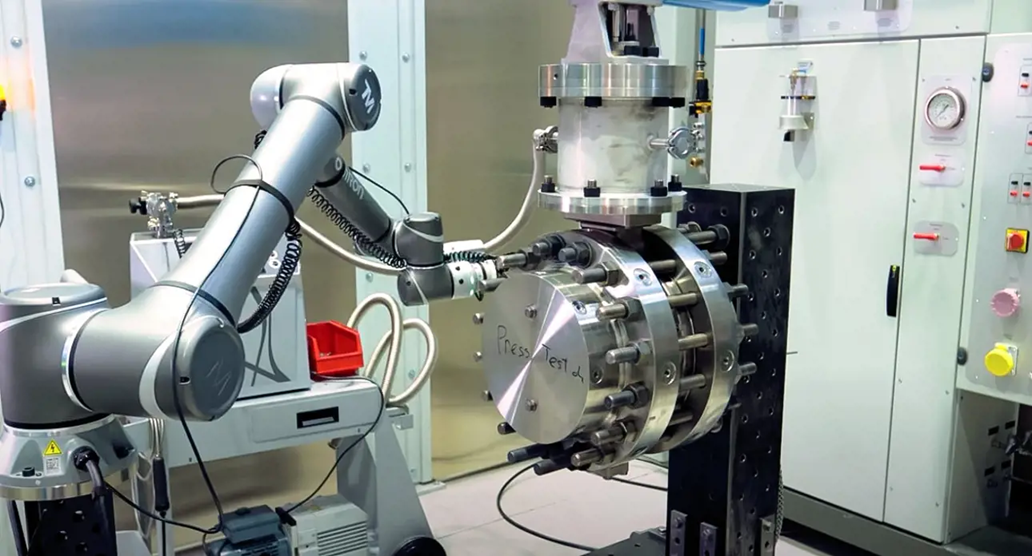

We take pride in the quality and safety of our laboratories and testing facilities. Typically, any doubts are dispelled as soon as customers step into the laboratory. High-pressure gas testing areas are strictly protected, and robots are often used to carry out leakage emission testing procedures, ensuring absolute safety for our technical team.

Value Created from Experience and Deep Knowledge

As in every other field, experience in valve technology brings both broad perspectives and practical value. Machines can handle the physical part of the testing process, but true knowledge and understanding lie with the people who operate them. Most of the team at our testing facilities across three continents have between one and two decades of experience, meaning that each valve inherits the value of hundreds of years of accumulated expertise in flow control.

Read More on the Topic

Read the first part of this series to learn more about the tests carried out on potential technologies and equipment before they become part of the tested valves as described above. In addition, look forward to the next part about the quality inspection process we perform on valves assembled at the sales and delivery facilities.