- 13/09/2023

- Valmet Flow Control

The effective applications of Neles V-port segment valve

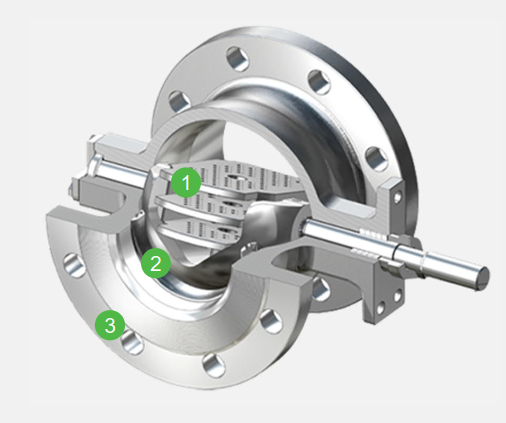

Neles V-port valve in the R-series is primarily intended as a control valve, but it can also be used for shut-off service. The R-series V-port segment valve is a good general control valve for most pulp and paper process applications. The valve can be fitted with an aerodynamic noise- and liquid cavitation-reducing (for example, steam and gas applications) Q-Trim™ segment.

1. Features behind unbeatable performance

– Accurate control with unique V-shaped flow port design with high maximum capacity and wide rangeability

– Frictionless operation secures smooth and long lifetime with carefully selected trim materials and bearing designs

– Secured backlash-free design delivers market leading control accuracy

|

|

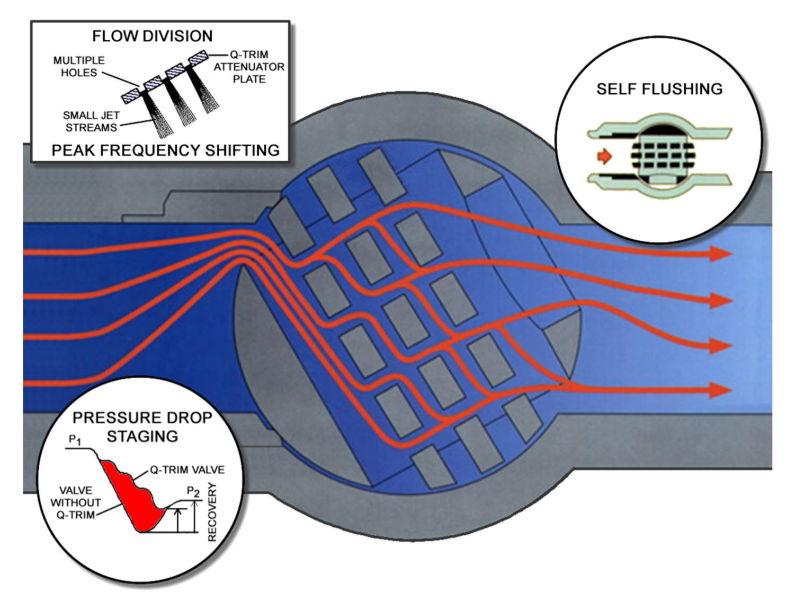

2. Q-Trim for efficient noise reduction design

Most pulp and paper mills have maximum noise levels for control valves. These limits are easily exceeded, especially for gas and steam applications, when using standard valves. High pressure drops, which occur during control of water and liquid flows, generate cavitation which may cause damage to the pipe system. The solution to these applications is the Q-Trim design.